What Is Middleware? Let SEEBURGER’s Integration Platform Open up Your Company to Industry 4.0

Industry 4.0 is requiring companies to be highly flexible and agile. Only by working quickly, cost-effectively and customer-oriented can they master the challenges of the digital age and gain a competitive advantage on the market. And to do this, they need an IT system that is up to the job. An integration platform is a middleware solution that lets you easily and securely network your in-house systems and applications with external applications and business partners’ systems.

Flexibility and agility are becoming key in the way companies set up and use their IT systems. They need to be able to meet customer expectations ever faster and more cost-effectively. This requires the highest degree of customer focus, shorter time-to-market cycles and a digital infrastructure that can serve these requirements. Traditional, standalone IT systems can no longer meet these demands. Modern IT ecosystems need to be able to network players all along the value chain.

Middleware integration – how to connect the chaos

Often these days, companies will have a mixture of isolated IT systems, some cloud-based and some still on-premises. Integrating these various IT technologies is one of the biggest challenges when moving towards Industry 4.0. And if not done holistically and well, the resulting hodgepodge of digital systems and applications leads to data loss, fragmented information and miscommunication.

Modern business processes need to be fully supported by IT on one seamless system. This requires the ability to seamlessly integrate existing, new and future applications. The previous strategy of developing bidirectional interfaces between the individual IT systems and updating them regularly no longer works. Today’s systems change too fast and have too high a variety of software and applications

In order to automate your business processes to make them more efficient and customer-oriented, data needs to be able to flow unhindered between parties along the value chain. And for data to flow between the various systems and applications in your IT landscape, you need an integration platform, or integration middleware, with standardized integration capabilities and services that seamlessly connect everything in your ecosystem.

Middleware is the solution – one integration platform to keep all systems together

The open interfaces of an integration platform let you quickly and easily integrate systems and applications along the value chain. Middleware integration is not only a ‛data juggler’ but it’s also a ‛data transformer,’ ensuring the right data is sent to the right system in the right format for that system. An integration platform is the ‛glue’ that keeps the disparate systems together.

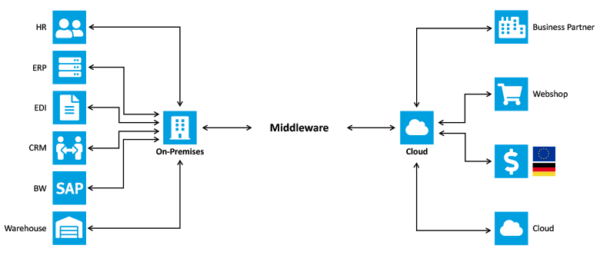

The following image shows an integration platform, also known as middleware, connecting a wide variety of internal, external, on-premises and cloud-based systems.

Middleware acts like a central delivery hub. Instead of connecting individual IT systems and applications through countless bidirectional interfaces, all systems are connected to one another via the integration platform. This central hub distributes data from one or more systems to the others that need it. The maintenance and monitoring tools for all the programs in the landscape are also based on the integration platform.

Why do you need an integration platform?

An integration platform can be used for several Industry 4.0 applications and beyond.

- Using an integration platform for supply chain integration

Supply chains worldwide are going through a digital transformation. And they need digital interfaces that enable real-time communication between the parties along the supply chain. Nowadays, orders, order confirmations, and delivery notifications and tracking for individual parcels are all transmitted electronically through an integration platform rather than by post, fax or email. Several advantages to digitally integrating business partners include:

-

- Full transparency through end-to-end monitoring of all documents transmitted, such as orders, delivery slips and invoices

- Significantly fewer errors due to standardized communication

- Real-time information on delays, breaks or other disruptive events in the supply chain helps you act immediately to resolve issues.

Staying in close communication with your suppliers through middleware integration of their systems lets buyers send detailed forecasts of their product needs to suppliers upstream. This means the supply chain starts to follow a pull system rather than a push system, with production upstream now determined by demand downstream.

- Use an integration platform to orchestrate just-in-time and just-in-sequence production

Interface vs. integrate: JIT (just-in-time) and JIS (just-in-sequence) production approaches are only possible if your systems are integrated with your suppliers’ systems (and not just interfaced with other systems). Manufacturers and their suppliers need to send constant updates on production so that the right parts are delivered at the right time. A wrong delivery would lead to delays in production. Switching to JIT or JIS ensures that only the material needed to complete a batch arrives in exactly the right amount at exactly the right time. Just-in-time production requires a coordinated information flow of production and materials along the supply chain so that material arrives when needed. For just-in-sequence production, material is ordered in the order and to the schedule of its assembly. - Using an integration platform in logistics

The main focus in logistics, transport, handling, storage and documentation has not really changed for decades. What is new, however, are the challenges of digitalizing these processes to make them compatible with the possibilities in Industry 4.0. These days, customers want to know immediately whether the goods they are buying are in stock, and they expect to be able to access this information wherever they currently are. Speed, flexibility, precision and availability are key competitive factors in the logistics industry. The very least is transparency at every step in the process. It is therefore essential that the operative side of the business is networked with the warehouse. A key factor behind successfully implementing Industry 4.0 elements is intelligent, information-driven logistics. This influences your

-

- ability to deliver

- reliability

- financial power

- flexibility

- reaction time

- processing quality and

- technical quality.2

The ongoing networking and integration of logistics processes as well as the decentralized real-time control of logistics networks within and beyond production facilities and organizations would simply not be possible without powerful middleware integration.

-

- Using an integration platform to enable smart services

Complementing the traditional business model of selling machinery and equipment, smart services are a supplementary or substitute high-margin revenue source for companies. Some of the things smart services enable include: - Selling functions as a service

Printer manufacturers, for example, not only sell printers and ink or other materials, they also gain extra business by doing print jobs (print as a service). Such services are particularly common in the 3D printing sector. - Predictive maintenance

Some equipment manufacturers offer their customers, for example, optimization, real-time monitoring or maintenance services. The operating data they collect from their machines enables them to make accurate forecasts about risks, potential maintenance or breakdowns. - Equipment as a service

In the future, digital services will open up the possibility of pay-per-use billing. The customer will no longer buy the machine. Instead, the customer will pay for how much it is used, either by time or by items produced.

- Using an integration platform to enable smart services

Machinery and equipment makers can ensure they are competitive by making their products ‘smart’ (i.e. connecting them to the internet). The end-to-end networking of smart services is becoming an ever bigger phenomenon thanks to integration platforms with Industrial Internet of Things (IIoT) capabilities. They give you the foundation to connect smart services to your existing systems.

- Using an integration platform in a smart factory

A smart factory stands for intelligent, networked, automated and digitalized production. At its center is middleware, which enables a self-organizing production environment in which people check and monitor work, but directly intervene at ever fewer points in the production process. RFID tags, industrial robots, autonomous mobile robots for transportation, automated warehousing and retrieval systems, and even drones communicate with one another. The integration platform not only connects these modern systems but also integrates older systems that would usually not be compatible with the new technology. This vertical and horizontal integration of technical systems, devices and equipment is the main job of an integration platform. - Using an integration platform to connect staff in a multinational company

Multinational companies usually have several ERP systems, each with their own master data. Why not use an integration platform to consolidate this data and also let your staff in all locations worldwide digitally exchange data and documents with one another? - Using an integration platform in e-commerce

Companies can hardly keep up with the speed of change in e-commerce. New software, new marketplaces, new sales channels. Companies need to be able to respond flexibly and quickly to market changes and provide customers with a personalized and uniform shopping experience across their various channels, whether an online shop, online marketplace, through a mobile device or in store. To ensure that the high volume of data in e-commerce flows smoothly between companies and customers, you need powerful interfaces. The best option would be to use middleware as a data hub between the various ERP and inventory management systems and the online retail platform. Automated data processing is particularly important for the aftersales market, as this is the only way to show and administer several hundred thousand items on your platform.

As you can see, an integration platform is a future-proof, flexible and secure solution for many business areas.

Give your organization a competitive advantage

The scenarios in this blog for using an integration platform clearly show the competitive advantages to be gained from middleware integration. These days, companies need to be able to share and analyze massive volumes of complex data more quickly and accurately than ever before. This will become more important as Industry 4.0 further transforms business life. This has led to a number of companies supplementing their on-premises IT infrastructure with cloud-based solutions. This means an IT ecosystem can quickly become too complex for you to get reliable, clean data exactly where and when it is needed. However, by taking a holistic approach of consulting, planning and implementation, you can quickly automate your business processes and integrate your business partners with an integration platform.

How SEEBURGER can help

Build sustainability into your company by integrating manufacturing systems with IIoT capabilities powered by the SEEBURGER BIS Platform. Connect everything and everyone across your ecosystem with our cloud integration services, packaged integration processes and ready-to-use mappings for every industry. Integrate and automate your ecosystem of manufacturing processes, equipment and facilities from the shop floor to the top floor.

Over 14,000 customers rely on BIS every day for secure and seamless connectivity, rapid scalability and compliance with industry data standards. Deploy our powerful integration platform as an iPaaS or with fully managed services in any cloud, hybrid or on-premises environment. With MFT, B2B/EDI, EAI/A2A, API, IIoT and Automation capabilities, BIS empowers any type of user to implement and support cost-efficient and smarter integrations between applications, people and processes.

White Paper

SEEBURGER Business Integration Suite (BIS) Platform Accelerate and Automate Business-Driven Innovation with Integration

Download1 Based on: Was kann eine Middleware? [What can middleware do?] (erlebe-software.de) (accessed 4th October 2021).

2 cf. Mit intelligenter Logistik auf die heutigen dynamischen Märkte reagieren [React to the dynamic markets of today with intelligent logistics]| dreiplus (dreiplus-beratung.de)(accessed 1st Oct 2021).

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Rolf Holicki

Rolf Holicki, Director BU E-Invoicing, SAP&Web Process, is responsible for the SAP/WEB applications and digitization expert. He has more than 25 years of experience in e-invoicing, SAP, Workflow and business process automation. Rolf Holicki has been with SEEBURGER since 2005.