Why Integration Platforms are the Central Hub for Smart Services

Smart Services are becoming more and more important throughout the entire product life cycle of mechanical engineering. As a digital service, Smart Services use and generate information and market service-based offerings via digital marketplaces and interfaces.

Smart Services as part of Industry 4.0 / Industrial Internet of Things

The digital transformation is adding value to products, machines, plants and in all industries at a rapid pace. Data is becoming a critical competitive factor and so-called IoT platforms are the starting point for Smart Services.

Machine and plant manufacturers secure their competitiveness by making their products smart and service-capable in order to offer Smart Services via Internet connections. The consistency of Smart Services connected through an IoT-capable integration platform is becoming increasingly important.

Digital Transformation Drives the Merger of Products with Information Technologies

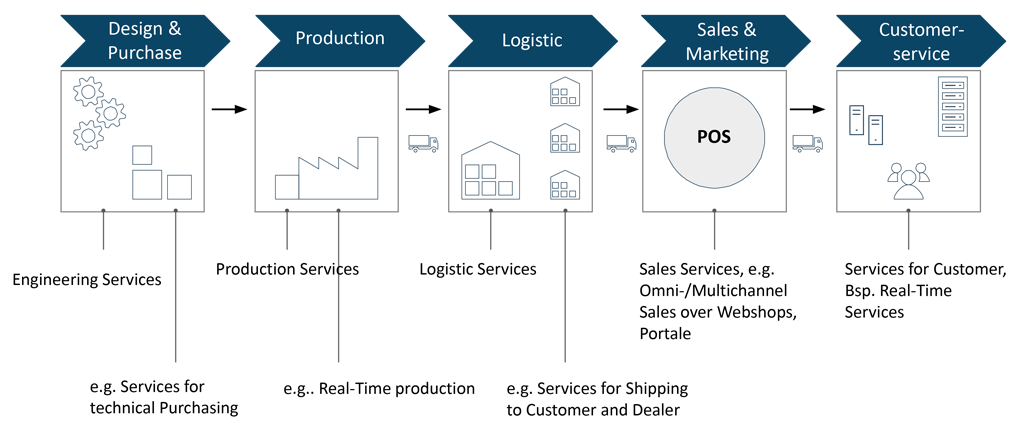

In the manufacturing industry products, machines and systems are increasingly merging with information technologies. This requires connecting digitally interacting players such as manufacturers, suppliers, customers and other business partners, but also IT systems, along the value chain as shown in Figure 1.

The larger part of the overall value creation moves towards after-sales service, i.e. services after the purchase of the product, machine or plant. Manufacturers as well as IT system integrators are therefore forced to offer services and solutions over the entire life cycle of the products, from product development to production and maintenance.

Like all other branches of the manufacturing industries, machine and plant manufacturers are also faced with the challenge of digitizing the value chain end-to-end in order to optimize processes, act more flexibly and innovate, including service-based business models.

Smart Products are the Basis of Smart Services

Smart products are products, machines and systems etc. that are equipped with sensors, controlled by software and connected to the Internet. They collect data from their environment, evaluate it and share it with other devices and systems. In the upcoming era of Industry 4.0 or the I(IoT) ‘Industrial Internet of Things’, data, services and processes as well as infrastructure are connected with each other to form value-added networks. These Smart Products are mapped on so-called (I)IoT platforms, which are a prerequisite for Smart Services.

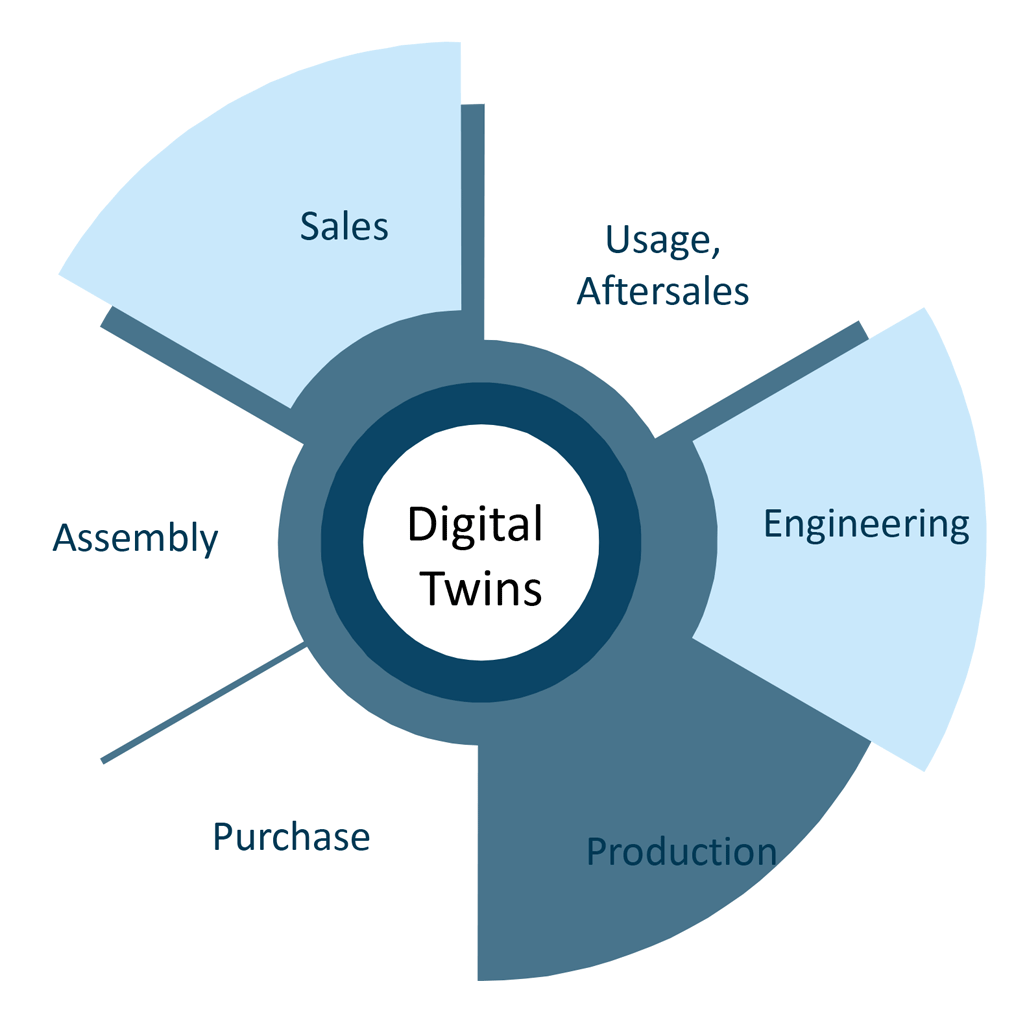

In the early phase of the product life cycle, virtual, digital models of real products, often referred to as ‘digital twins’, are helpful. A digital twin is a virtual representation of a physical product and is created during the development of a product. Thus, the physical product is enhanced by data-based services. End users will then receive not only a product, but a product with associated services.

Smart Services via Digital Twins

The physical smart product equipped with sensors is accompanied by its digital twin throughout its entire service life. Built-in sensors on the real products and machines thus constantly transmit information to the digital twin as shown in Figure 2.

The digital twins allow simulations and analysis based on production data. Production facilities and processes can be improved upon, as well as possible incidents being anticipated. Due to these anticipations, appropriate countermeasures can be developed without impairing the physical system.

Today, both the lack of availability of data and the heterogeneity of the IT systems used, prevent the continuous use of digital services. For complex services, suitable process and system integration with existing service processes is required in addition to a growing database.

A suitable integration solution is required both for the exchange between the digital twin of a product at the manufacturer, operator, user or service provider and for the exchange between different processing systems.

Integration Platform as the Central Hub for Integrated Smart Services

The integration platform connects smart products with existing systems in heterogeneous IT landscapes.

Value creation is driven by exponential growth in data-generating and data-processing systems. Business processes are supported during their entire product life cycle along the value chain of a company by plenty of different IT systems. Usually, several systems are involved in a process, which interact with each other via APIs (Application Programming Interfaces). These provide selected system functions in real time for use by other applications.

Up until now, interfaces have mostly been created on demand, often on call, by different teams or with the help of external service providers and on the basis of various technologies.

The result is high complexity, inflexible systems and uncontrolled growth – i.e. no uniform security standards and no central control of who has access to which systems. Quality also suffers because no centrally managed layer monitors the API profiles for the different systems.

API Management empower real-time Smart Services

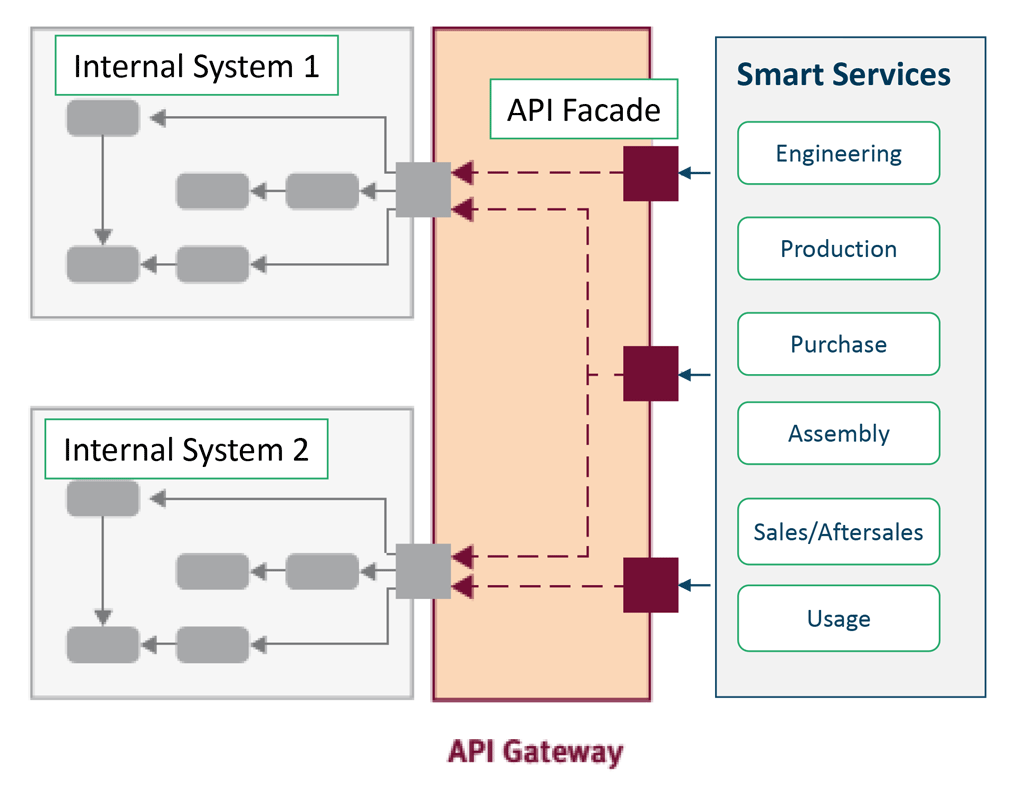

The increasing demand for APIs challenges IT departments. They must develop, provide and document interfaces, manage their own and third-party APIs, ensure security in data access and maintain an overview of granted authorizations. Internal systems – especially those with business-critical functions – are usually part of a grown IT landscape. They are adapted to the requirements of the company, proven and stable. On the other hand, they often use older technologies and often run unchanged for a long time. Generic interfaces often exist, e.g. to read out database contents. However, these do not meet the demand for Internet-ready APIs tailored to the specific user group, as is required in the digitization environment, for example for Smart Services as shown in.

One solution concept is the formation of an API Gateway as shown in Figure 3. Only this facade is visible to the outside; the data-holding applications and business logic are hidden behind and protected by the API facade. By hiding the true complexity of internal systems, API facades ensure that different systems can communicate easily and securely with internal applications. The API facades are designed specifically for the requirements and intended possibilities of the API users. They are provided by an API gateway, which simultaneously controls and secures access. Because modern apps and applications communicate exclusively with the API facade, the internal systems behind it can also be replaced or modified at any time.

Learn more about SEEBURGER solutions for integration platform, API management and for the IoT-Integration mechanical and plant engineering industry.

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Dr. Seref Erkayhan

Dr.-Ing. Seref Erkayhan is product manager for engineering (CAD/CAx) and product data exchange at SEEBURGER. He heads the division for mechanical and plant engineering.