Predictive Maintenance – Part 2: How does predictive maintenance work?

This article follows our piece on Predictive Maintenance 101 – What Is It and Where Is It Used? and looks at the technologies behind predictive maintenance. Sensors of all kinds play an important role, capturing a large quantity and variety of data. This data is collected and analysed to glean important insights into the condition of the equipment. This allows you to take appropriate measures to prevent malfunctions or further damage to your machines. Increasingly, artificial intelligence and machine learning are being used to support predictive maintenance. And underpinning it all is powerful data integration and automation. Let’s find out more!

Predictive maintenance is inextricably linked with areas such as the internet of things (IoT), industry 4.0 and big data. It involves using sensors to permanently monitor components. These sensors measure things such as vibration, humidity and temperature. Autonomously learning algorithms then evaluate the collected data and identify any defective components. This lets you replace them before damage actually occurs.

Predictive maintenance means less downtime

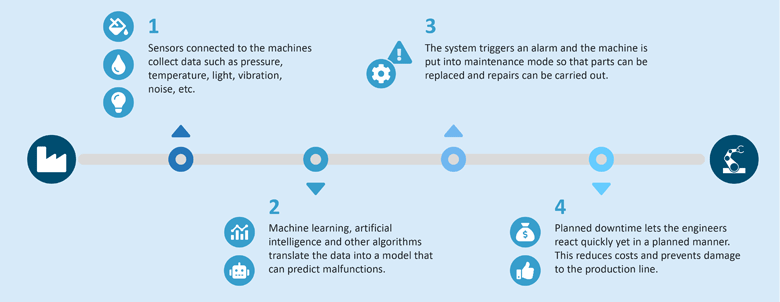

The image below shows how predictive maintenance helps prevent unplanned downtime. To begin with, various sensors collect helpful information on a machine and its environs. This is fed into a system where it is analysed using AI. If the analysis shows that a component is failing or at risk of failing, the system triggers an alarm. This lets you proactively replace the part before it can shut down the machine or cause real damage.

How sensors are used in predictive maintenance

There are many types of sensor available, and several can be used in predictive maintenance. The following chart[2] contains some of the many technologies:

| Sensor Type | Description |

| Acoustic sensor | Acoustic sensors measure sound levels and convert this information into digital or analogue data signals. |

| Motion and occupancy sensors | Occupancy sensors detect the presence of people and animals in a monitored area, while motion sensors detect movement of people and objects. An occupancy sensor gives a signal when something is still, whereas a motion sensor doesn’t. |

| Biosensors | Biosensors detect biological elements such as organisms, tissues, cells, enzymes, antibodies and nucleic acid. |

| Chemical sensors | Chemical sensors measure the concentration of chemicals in a system. It is usually trying to identify a specific chemical from a mixture. A CO2 sensor, for example, only detects carbon dioxide. |

| Pressure sensors | Pressure sensors are related to load cells and measure the force exerted by liquids or gases. Pressure is measured in terms of force per unit surface area |

| Flow sensors | These sensors record a liquid’s flow rate. They measure the volume (mass flow rate) or the quantity (flow rate) of liquid that has passed through a system in a given period of time. |

| Motion velocity sensors and accelerometers | Motion velocity sensors are linear or angular and indicate how fast an object is moving or rotating along a straight line. Accelerometers measure changes in velocity. |

| Load cells | Force sensors detect whether a physical force is being applied and whether this exceeds a certain threshold. |

| Humidity sensors | Humidity sensors detect the humidity (amount of water vapour) in the air or in a mass. Humidity can be measured in several ways. |

| Light sensors | Light sensors detect the presence of (visible or invisible) light. |

| Position sensor | A position sensor measures the position of an object. This can either be absolute (location) or relative to certain markers (displacement). Position sensors can be linear, angular or multi-axis. |

| Radiation sensor | Radiation sensors detect radiation in the environment. Radiation can be detected using scintillation or ionisation. |

Processing the data

A huge challenge in predictive maintenance is how to process the sheer mass of data that the sensors capture. This is necessary to make reliable statements about the condition of a system and any emerging malfunctions. As the sensor data is in several different formats, processing is a complex challenge.

How artificial intelligence (AI) helps in predictive maintenance

Artificial intelligence can recognise patterns, such as if a change in certain key performance indicators in the past had been followed by an element failing.[3] If a breakdown is imminent, artificial intelligence can deduce what needs to be done and, with robust process and data integration, trigger counter measures. These can include reserving resources, sending out a service request, alerting a service provider, and adjusting the production schedule.

Networked systems in predictive maintenance

As you can see from the above, the AI-driven systems in predictive maintenance cannot work in isolation. They need to be connected to other systems and to exchange data with these. Depending on specific needs, it may make sense to connect to your ERP system, your warehouse management system, your manufacturing execution system or facilities management system with its maintenance schedule. They need operational and process data, as well as data from sensors on various pieces of equipment.

An integration platform, such as the SEEBURGER Business Integration Suite (BIS), can become the hub which manages your data logistics. Why not take a look at our on-demand webcast to find out more?

Conclusion

Predictive maintenance systems are one of today’s most successful industry 4.0 solutions. They significantly reduce the unplanned downtime that costs manufacturers an estimated $50 billion annually. A large number of major manufacturers have already upgraded their operations and operating models with IoT and AI-based analytics to minimise risks and accelerate time to market. At the heart of all this activity is data, alongside its logistics, processing and integration. There is significant potential in a company‘s data – and not just for maintenance!

A good integration platform and corresponding applications let you overcome the challenges in predictive maintenance. In this age of digitalisation and networked systems, data can give you valuable, practical information about likely scenarios. Contact us if we can support you in the introduction and integration of data-based capabilities.

[1] Based on: Was ist Predictive Maintenance? Definition, Anwendung und Beispiele (industry-of-things.de)[What is predictive maintenance? Definition, application and examples] (accessed 15th Nov. 2021).

[2] Based on: DUP_1102_InsideTheInternetOfThings.pdf (deloitte.com) (accessed 17th Nov. 2021).

[3] Cf. Was ist Predictive Maintenance (Vorausschauende Wartung)? – Definition von WhatIs.com (techtarget.com) (accessed 17th Nov 2021).

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Rolf Holicki

Rolf Holicki, Director BU E-Invoicing, SAP&Web Process, is responsible for the SAP/WEB applications and digitization expert. He has more than 25 years of experience in e-invoicing, SAP, Workflow and business process automation. Rolf Holicki has been with SEEBURGER since 2005.