Let cutting-edge technology give your supply chain some muscle

Many companies today operate on a global scale, with supply chains consisting of numerous suppliers and crossing multiple national borders. In order for outsourced processes and entire supply chains to continue to work, they need to be redesigned to meet the challenges of today’s business world. This article looks at some of these challenges and how technology can help you overcome these challenges and be better prepared for the future.

The global economy is currently in supply-chain shock. Along with the continuing COVID-19 pandemic, events such as the freighter Ever Given blocking the Suez Canal for several weeks have caused long-lasting global supply issues. However, it’s not always global events that are responsible for disruptions in the supply chain. Even localized issues can cause a link to break in the supply chain, such as weather events, a supplier going bankrupt, technical issues or IT problems. You can read more about the fragility of global supply chains and the reasons for this in part 1 of this series.

This article also looks at how to build a future-oriented global supply chain. You’ll discover how the newest technology can help strengthen your supply chain, along with tips on how you can react quickly to the external factors threatening your supply chain – even in a crisis.

Value-adding and non-value adding steps in the supply chain

As companies have recently started to focus their attention more on their core business, many choose to outsource certain services and processes to third parties, such as manufacturing components and pre-work. Companies also outsource non-value adding elements such as facility and plant machinery operation and maintenance, security services, catering, IT infrastructure and services, and other support services. The result is an unwieldly network of interdependent supply relationships that requires careful planning to ensure that the chain does not snap at its weakest points.

In order to anticipate risks, your business continuity management efforts should not be limited to inside the company – rather they should encompass the whole supply chain. Any disruption or change within your global supply chain needs to be addressed with appropriate counter measures to ensure your company stays competitive.

Challenges in redesigning a supply chain

Redesigning a supply chain is complex and presents companies with significant challenges, which are detailed below.

Keep track of the whole supply chain

One of the biggest challenges is to fully understand and nurture the network of relationships along the value chain. This is no small feat; a large corporation’s direct supplier relationships alone typically go into the thousands.

Analyze risk along the entire supply chain

As a result of the sheer number of companies involved in a supply chain, it’s important to take a structured approach and set clear priorities when redesigning a global value network. You’ll need to assess the significance and risk to all parties, both upstream and downstream, and to the value chain as a whole. If necessary, you’ll need to take measures to safeguard the supply chain from these risks. A supply chain should be designed with an eye on both cost and risk at all times.

Ensure legislation is complied with along the supply chain

Another challenge is legislation, particularly when outsourcing parts of the supply chain. In fact, in 2021, the EU introduced the Supply Chain Act, making companies liable for the actions of their suppliers. Companies also need to know and follow the e-invoicing rules for the countries in which they

do business. These vary from country to country, making it tricky for global players to ensure compliance.

Define and communicate expectations upstream

Ensure that your suppliers and service providers know exactly what you need from them, and that it is specified in a contract. You should regularly check that they are complying with the terms. An EDI connection can be helpful for this as it automates the agreements between your company and suppliers during onboarding, making it easier for you to

comply with and monitor requirements.

Get information flowing throughout the supply chain

Another challenge is establishing a fast and reliable flow of information throughout the supply chain. All partners in the digital value network need to be able to communicate with each other quickly and flexibly with the latest technologies, whatever the circumstances.

You need current data to make the right decisions for your company. If you cannot see what is currently happening in a particular process, you can’t react to issues that arise. This may involve adjusting the delivery date, changing the source of supply or the type of transport. You can harness the advantages of today’s technology, otherwise known as industry 4.0, beyond production, and enable:

- Complete transparency

- Networked processes

- Small batches

- More product variety

- Decentralized supplier and customer management

Transparency in the supply chain

Recent research has shown that the Covid-19 pandemic has made it even more important to have transparency in a supply chain. According to the 13th Hermes Barometerii, an annual survey run by the German logistics giant, 47% of the logistics decisions makers asked felt that transparency was extremely important in a supply chain. In addition, 40% of those surveyed agreed with the statement that information needs had significantly increased in their own supply chain due to the pandemic and increasing economic uncertainty.

Also according to the 13th Hermes Barometer, the biggest obstacles to building a more transparent supply chain are:

- Security issues (46%) and lack of trust

- Exchanging data with partners (43%)

- Insufficient human resources for creating a digital supply chain (53%)

Those companies that already have a digital and transparent supply chain and actively protect it against potential risks already have a competitive edge. Companies whose supply chains are still not completely digital, networked or transparent should therefore act quickly in order to remain competitive.

Using cutting-edge technologies in the supply chain

Companies use technology in their supply chain to automate their processes. This reduces sources of error, eliminating the need to manually transfer information between systems, or even paper-based steps. Adopting these modern technologies in the supply chain is an important step towards designing lean processes and reducing costs. Below are some of the technologies companies are adopting in the digital transformation of their supply chains.

CLOUD

Companies are starting to focus on new and hybrid IT architectures when evaluating their IT infrastructure. Alongside on-premises IT systems, we are starting to find more cloud technology in global supply chains. Cloud-based applications have become an integral part of many companies’ transformation strategies. For us here at SEEBURGER, most customer projects in the last few years have included migrating established applications to a cloud environment. The benefits of cloud-based IT solutions in the value chain are as follows:

- Cost and process transparency

- High availability

- Scalability

- Flexibility

A significant value in using cloud-based applications in logistics is that it lets you quickly and cost-effectively integrate external partners and suppliers into your back-end processes. As you’ll see below, a cloud-based integration platform has an innovative effect on the entire supply chain worldwide.

EDI / API

The supply chain of today is characterized by complex process management and countless trading partners. It is therefore difficult to ensure error-free processing without adopting a form of electronic data interchange (EDI and/or API ). This is because today’s supply chain management is not just about goods moving from supplier to customer. It’s also a stream of complex information and data, from transmitting product details to automatic order processing and payment. To prevent breaks in the chain, each party has to receive the information it needs, including last-minute changes, and process this information as quickly as possible. This would be simply impossible with manual methods such as paper, fax or even email. The power of EDI or APIs and professional API management is that a company and its business partners are networked and integrated in real time. This was previously only possible within the four walls of a company.

Blockchain

Using a blockchain allows data from the supply chain to be stored in an immutable, verifiable, and traceable manner, while still being viewed by all participants in the value chain. One advantage of blockchain is that customers can seamlessly trace the origins of their goods. This makes it easier to shop sustainably. On the other hand, when automating part of the supply chain, it is the manufacturers who benefit from blockchain as a low cost way to prove the quality and origin of their products. Blockchain technology can help make consumption and production more socially just, ecological and integrated, and this helps increase sustainability. You can also complement blockchain technology with other technologies such as the internet of things (IoT), or others to further strengthen your global supply chain.

Artificial Intelligence

In order to avoid empty spaces on shelves, you need to plan ahead. Artificial Intelligence (AI) can help you make more reliable predictions, and can be used particularly effectively in supply chain management. However, although AI technology is promising, its use in supply chains is still in its infancy. Currently, the most common applications are sales and activity forecasts and inventory management.

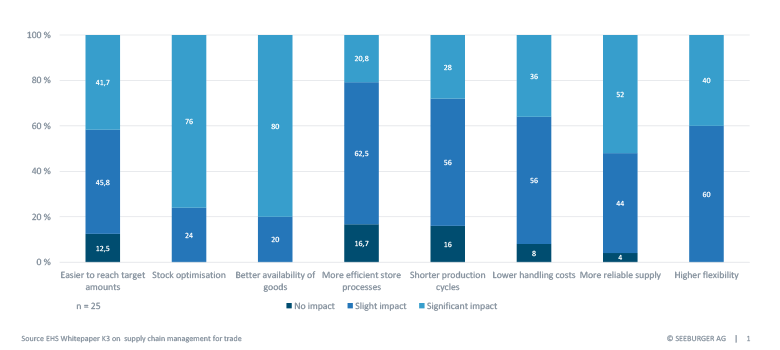

The graph above illustrates the economic effects companies expect if they start using artificial intelligence (AI) in their supply chain management. For example, 80% of those surveyed expect that AI would improve the availability of their goods. According to Accenture, AI can automate multiple planning processes and inventory optimization and execution with a focus on making decisions automatically—without human intervention. AI may transform supply chains — and in today’s environment, transformation isn’t an option anymore.

Sustainably redesigning a supply chain

Climate change and the environment are important to all of us, and companies across the globe are making changes toward sustainability. More purchasing decisions are being made from an environmental perspective, and parties along the supply chain are being put under pressure to improve the environmental credentials of products. Companies are being forced to find solutions for these new demands. While those in supply chain management are looking for more sustainable packaging and transportation options, there are also calls to improve the transparency of the chain so that the individual components and raw materials can be traced to the source.

The Supply Chain Act in the EU makes companies liable for any human rights violations committed by their suppliers. This will further increase the need to ensure a sustainable chain, and companies need to start preparing for this now.

Gain a competitive advantage with a transparent supply chain

Pandemics, natural disasters and political factors have increased the risk of disruption to supply chains worldwide, and intensified the trend toward digitalization and automation within the supply chain. At the same time, customer demand for sustainability is re-shaping the supply chain. Even members of the supply chain, who at first glance would seem to have no relationship to the end consumer, are affected. They may be required to ensure their methods are sustainable, or to provide a certificate of origin, or to comply with specific legislation. This is one reason having a transparent supply chain is an underestimated competitive advantage.

Conclusion

Companies need to examine their supply chains now, so that they’re not late to the party. They need to decide what to optimize and how to do it, starting with a clear supply chain strategy, comprehensive knowledge and targeted use of new technology.

SEEBURGER has a number of solutions to help you digitalize your logistics chains and accelerate your processes. Our flexible on-premises, cloud, and hybrid operating models let you stabilize, innovatively redesign and improve cost-efficiency of your supply chain.

i David Loseby, https://blog.scanmarket.com/insights-on-american-legislation-effecting-supply-

chain-management

ii cf. hermes-barometer-13.pdf (hermes-supply-chain-blog.com)

iii cf. KI in der Supply Chain – com! professional (com-magazin.de) [

AI in the Supply Chain].

iv Patricial Riedl, Jaime Lagunas, https://www.accenture.com/us-en/insights/artificial-

intelligence/reinventing-the-supply-chain July 15, 2022.

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Brent Tisdale

Brent Tisdale is a Vice President of OmniChannel Sales at SEEBURGER, a global market leader in business integration software. He has more than 30 years’ experience working for luminary companies like IBM and General Electric where he has streamlinedcomplex business processes for many industries including Retail, CPG and Discrete Manufacturing. He has a Six Sigma Greenbelt earned from his years with GE which he utilizes to gain a deep understanding of business process challenges and the suggested integration options. He was the Co-captain of the 1979 Holiday Bowl Champions. The first Bowl game ever won by Indiana University (Bloomington) Football team.