Interoperability – a core requirement of industry 4.0

On the road towards Industry 4.0, companies modernize their IT infrastructure and the digitalization of business processes to build new data-driven services. For these services, many internal and external stakeholders must work together. A prerequisite for this is the interoperability of systems across Lines-of-Businesses and companies.

On the road towards Industry 4.0, companies modernize their IT infrastructure and the digitalization of business processes to build new data-driven services. For these services, many internal and external stakeholders must work together. A prerequisite for this is the interoperability of systems across Lines-of-Businesses and companies.

Industry 4.0 / Industrial Internet of Things changes industrial value chains

Data is the new oil, so postulated by a long-time customer of ours. This tier-1 supplier from the automotive industry focuses on the expansion of its industry 4.0 infrastructure for both internal and external scenarios.

The future of industrial production is data-driven. Thus, for the customer the product alone is no longer the key, but its functions, capabilities and additional value-added services are of paramount importance. To create a valuable customer experience in an individual and changing environment, these areas must be continuously measured, monitored and kept available. Services have to be delivered directly during the use and interaction with the product.

Integration ensures interoperability in value chains

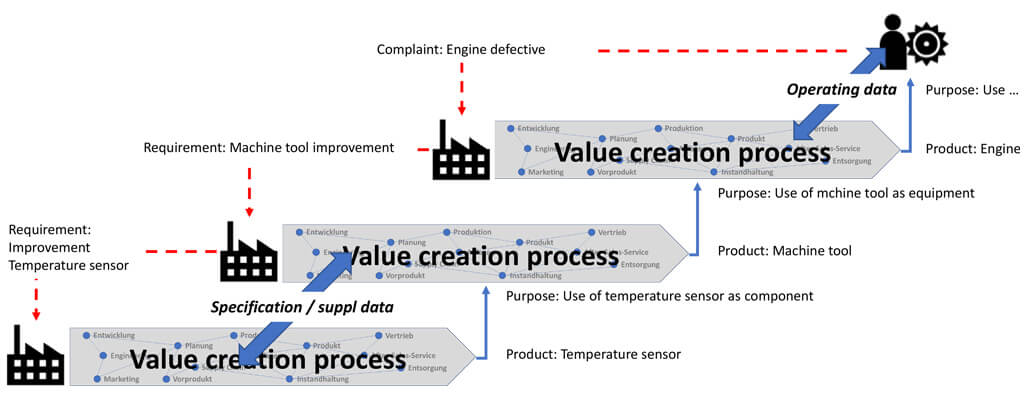

The mining and transport of data has some challenges, but alone does not provide any added value. A high level of data quality is needed in the entire supply chain from supplier to end customer in order to derive reasonable conclusions, or to use it for further processing.

Uniform semantics of data, especially of the central reference objects for products, processes and resources are crucial. Only by combining this (master) data with machine and process data, which is increasingly available from sensors, simulations and analytics, companies can improve their decision-making, support work processes with new digital services and thus increase the quality and productivity of operational and technical processes.

Think of data-driven services for:

- Predictive & preventive maintenance

- Assistance and optimization

- Change and reconfiguration of systems

These data-driven services support operational and business-critical decisions with a common ‘language’ that must be spoken and can be correctly translated into the organizational structures of the partners involved. How this ‘knowledge’ can be shared between supplier and customer users in cooperation and transformed into added-value for both sides is the focus of Industry 4.0 implementations. The consideration of this within the entire value chain with additional business partners and suppliers is still largely ignored.

VDMA Industry 4.0 Guide

In its new Industry 4.0 Guide ‘Interoperability through Standardized features’, the VDMA focuses on this connection between today’s master data standards and its use in Industry 4.0 implementations. Based on characteristics that are available in a standardized format and description, reference objects can be uniquely identified and tagged, allowing systems to understand the data correctly for further use in subsequent processes such as purchase orders, production orders or maintenance instructions.

Interoperability in value chains as a basis for data-driven services (case study from the VDMA guidelines)

The VDMA guideline deals with essential aspects of structuring and describes procedures for master data management and their use in the context of Industry 4.0 and supports the reader in the self-assessment of their company.

It is a big step towards a successful Industry 4.0 implementation if companies are automatically providing and exchanging their product, machine and operating data on standardized features combined with standardized transmission formats. To secure the interoperability of systems and people across Lines-of-Business and between companies, strong integration competences are needed to transform company-owned business knowledge into data-driven services with standardized formats and semantics. This is a key element towards using and offering data-driven services within B2B interactions and for connecting information, operational and engineering technology systems (IT/OT/ET) within the value creation process.

As a hybrid integration platform, the SEEBURGER Business Integration Suite enables the cross-functional and cross-company interoperability of systems, processes and things. Learn more about our services and solutions for your transformation to industry 4.0.

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Viktor Schubert

Viktor Schubert is Product Manager for IoT/Industry 4.0 at SEEBURGER and has been working in the field of data and process management (B2B/PLM/MES) for over 10 years. He is active in the standards committee for mechanical engineering NAM (Normenausschuss Maschinenbau) of the German Institute for Standardization DIN (Deutsches Institut für Normung) as well as in task forces of the German Engineering Federation VDMA (Verband Deutscher Maschinen- und Anlagenbau) and is involved in the standardization and development of these areas in the "Industry 4.0" environment.