Industry 4.0 and Lean Management – How to Manage the Chaos

Value chains are becoming increasingly complex and networked. This is not only due to globalisation, but also to the increasing use of industry 4.0 elements. Lean management methods provide valuable approaches for companies to design their systems more efficiently and sustainably. This article looks at the demands these approaches place on data logistics and how they can optimise the phases in the data cycle to help your company work even more efficiently.

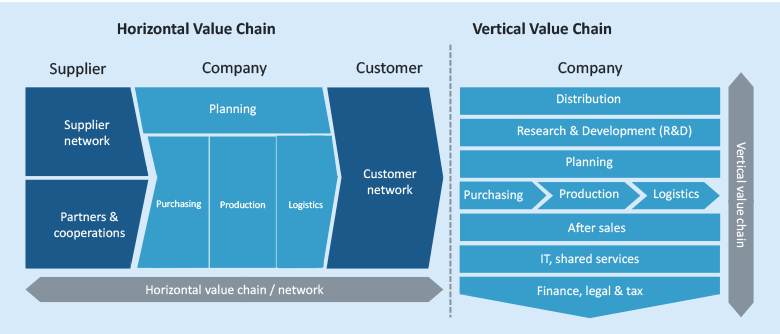

Ever shorter product life cycles and innovation cycles, an increase in customisation and rising pressure on costs mean that value creation networks are becoming much more dynamic and complex. This development has been encouraged and accelerated by digitalisation, which has made horizontal and vertical value chains more efficient. At the same time, lean management methods help you work more sustainably. When these methods are combined with the potential in industry 4.0, there is huge potential to increase efficiency and innovation.

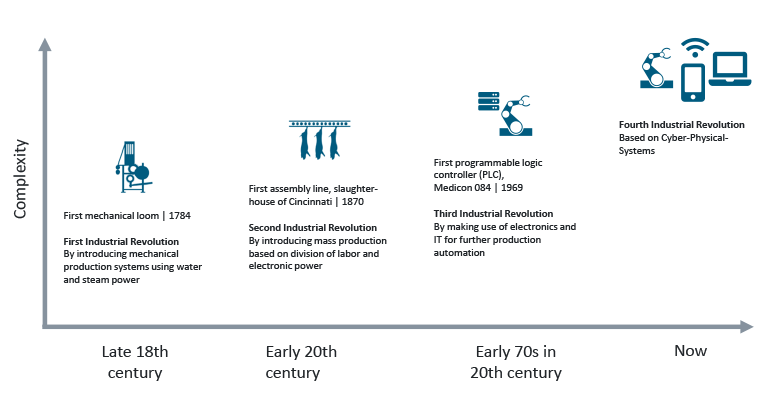

The evolution of the value creation chain

A natural progression of horizontal and vertical value chains is intelligent networking, in which computer-based machines and systems are linked to each other and to other information and communications technology (ICT) systems via the internet. At the same time staff, customers and product users are easier to reach through digital transformation. This combination of cutting-edge production facilities and technically integrated stakeholders and consumers opens up all sorts of new business possibilities.

Simplify with lean management

A big challenge in industry 4.0 is that it can quickly get complicated. However, by using lean management methods and designing your processes to be as simple yet effective as possible, you can reduce this complexity.

What are the goals of lean management and industry 4.0?

Lean management and industry 4.0 approaches actually follow broadly similar goals. The methods in lean management aim to improve time, quality, costs, safety and motivation. Industry 4.0 opens up new ways of tailoring products and new ways of selling them. The following chart illustrates the similarities between lean management and industry 4.0.[2]

| Lean Management | Industry 4.0 | |

| Issue | Waste, inefficiency, loss of productivity | Complex systems, shrinking batch sizes, high degree of flexibility required |

| Approach | Holistic (people – technology – organisation) | Technology-centred and based on data science |

| Basis | Stability, standardisation | Networking, adaptivity |

| Management approaches | Flow, FIFO, pull-based | Dynamic, situation-dependant |

| Information gathering | Current place, current material | Situation-dependant usage of real time data |

| Improvement | Through staff responsiveness in daily business. | Self-optimisation, predictive |

| Secondary goals | Eliminate non-value adding activities, gear processes towards giving customers added value, use resources efficiently | Increase digital maturity level to allow transparent and dynamic management of systems and processes |

The relevance of data logistics

Data is becoming extremely important for the current and future business models spawned by industry 4.0. It therefore now has a significant economic value for many organisations, regardless of their size. However, in order to successfully adopt industry 4.0 elements, you need to be able to manage your data along your entire value chain. This is where lean management can help. Its methods help you optimise your data logistics so that your data

- arrives at the right place,

- at the right time,

- in the right amount, and

- at the right quality

to be used in a targeted way in your value creation process.

We all need different things from data logistics

The demands on your data logistics vary by where the step is in the chain, and whether it’s a horizontal or vertical value chain:

How to optimise each stage of the data cycle with lean management

In order to help us manage the challenges in data logistics, it’s helpful to divide and consider it in four stages:

- Generating data

- Transmitting data

- Storing data

- Using data

Taking a lean management approach reduces complexity within each of the four phases of the data cycle. This process can be structured and facilitated by asking the types of question below.

Optimising data generation with lean management

The issues at this stage tend to be due to the quality, origin and reliability of the data generated. By asking a few pertinent questions in advance, it is easier to select data that you can actually use:

- Data selection

- Have we defined why we will use the data?

- Have we ensured that all the data we need is actually available?

- Have we defined the type and amount of data we need?

- Have we ensured that irrelevant data will be filtered out?

- Do data protection laws allow us to process the data?

- Data quality

- Do we have data available in the quality we need?

- Is the data detailed and current enough to use?

- Is the data in the right format for our needs?

- Data origin and format

- Is the data in a digital format?

- Is data collection standardised and automated?

- Do we need to collect data manually?

- Is data supply centralised or decentralised?

- Do we need the data in real time?

Optimising data transmission with lean management

Stable data streams are essential. The following questions are helpful for optimising data transmission:

- Are there any breaks or conversions in data transmission?

- Do we need to convert the data to a different format to use it?

- Do we need to validate the data before sending?

- Do we need to enrich or complement the data from another source?

- What data protection issues do we need to consider?

- Does the data need digitising?

- Is the data transmitted in real time or as and when?

- Do we need data to be transmitted in real time?

Optimising how data is stored with lean management

Lean management requires relevant data to be saved to the right place. The following questions help here:

- Is information missing, which stops processing?

- Are data and information available at just the right time?

- Can employees easily find the information they need?

- Is the data in a suitable format to be processed?

- Do we need to control access to this data?

- Will the data be replicated in redundant storage?

- Does the data need to be saved in a tamper-proof way?

- Should data be stored centrally or decentrally?

Using data well

Business processes along vertical and horizontal value chains often rely on data. Consider the following questions to help you use your data well:

- Is the data complete and available in the right quantity and quality?

- Has the data been made ready for use?

- Have the most suitable techniques been used to analyse the data?

- Will we use the results?

- Will decisions be made based on these results?

Good data logistics needs a solid foundation

Before you can implement lean, sustainable data logistics, you need to do the following groundwork:

- Digitise and automate manual, analogue processes,

- Connect you various IT sub-systems,

- Create interfaces to suppliers and customers

- Connect up legacy systems.

Once you have solved these challenges, you can

- simplify your data logistics,

- collate and analyse data from a variety of sources in real time,

- Accelerate your processes and enable new ways of working in-house, as well as with customers and suppliers.

How can SEEBURGER help?

The SEEBURGER Business Integration Suite offers you great potential for seamlessly networking machines, sensors and devices with your and your partners’ IT systems. Let us help you set up your data logistics for industry 4.0 and smart technology. Our consultants offer excellent support for your digital transformation and industry 4.0 initiatives, with process-based, holistic consulting from the planning stage right up to using your smart tech and industry 4.0 enabled processes. Discover how your company can react quicker and more responsively to your customers‘ needs and tailor your offering to their individual needs. And discover how you can optimise and automate your business processes.

[1] cf. Sour: Lernen 4.0: Chancen und Perspektiven für Fachkräfte für Arbeitssicherheit. Digitalisierung und Arbeitsschutz – (sifa-sibe.de) (accessed 22.10.2021).

[2] How lean management and industry 4.0. complement and contradict each other: based on the guide „Industrie 4.0 trifft Lean“ [industry 4.0 meets lean], VDMA Verlag, page 9 (accessed 25th October 2021).

[3] cf. Sour: Kooperationsprojekt »Lean 4.0« (fraunhofer.at) (accessed 02.11.2021).

[4] cf. Sour: PWC: Industrie 4.0: Chancen und Herausforderungen der vierten industriellen Revolution

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Rolf Wessel

Rolf Wessel has been product manager at SEEBURGER for software applications and services for electronic business data exchange since 2010. His focus is on solutions for SAP, electronic invoicing (e-invoicing) and innovations for the digitalization of business and technical business processes. The Forum elektronische Rechnung Deutschland (FeRD) appointed Rolf Wessel as an expert. As project manager at the United Nations Centre for Trade Facilitation and Electronic Business (UN/CEFACT), he develops international trade facilitation and establishes standards for electronic business processes. Furthermore, he represents the German delegation of the FeRD at the Franco-German workshop with the Forum National de la Facture Electronique (FNFE) and thus supports the government initiative for international standardization and harmonization of e-invoicing processes. He is a member of the working committee "Electronic Business" at the German Institute for Standardization. (DIN) and Association for Electronic Invoicing (VeR). Rolf Wessel graduated in business informatics (FH) with a focus on financial management and production planning. After working in the electrical, financial, consumer goods, software and mineral oil industries, he had been a systems analyst and IT project manager in the retail and logistics sector from 2003 to 2010.