How Data Logistics Adds Value to Your Value Chain

If a company wants to survive in the market, they need to digitalise their vertical and horizontal value chains. This is something else which the COVID-19 pandemic has made clear. Every couple of years, the Digital Transformation Index shows us how companies worldwide are digitally transforming. Find out in our blog article how you can remove any obstacles to digital transformation from your value chains and what advantages await you. In these times of digital transformation, advancing globalization and demographic change, the economy is facing major challenges. If you want your company to remain competitive in the long term, your value chain (or value network) needs to be at the centre of your digitalisation work.

Even though there are certain risks associated with digitalisation, the opportunities for your company far outweigh these. The customers of today want high-quality tailored products at low prices, and as fast as possible.[1] It’s a trend which is only set to increase, and end customers now expect products and services to be personally tailored to them.

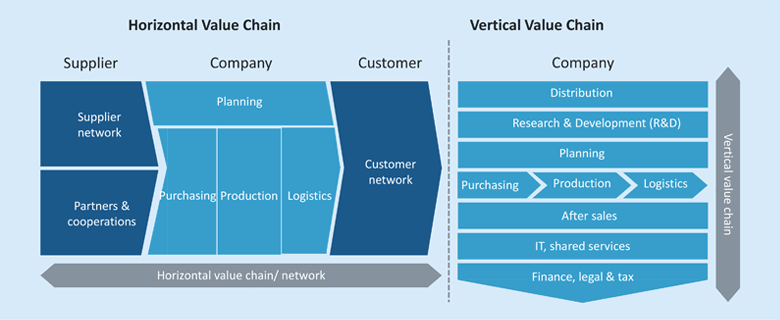

Horizontal versus vertical value chains

This expectation has a significant impact on why a company needs to digitally transform its vertical and horizontal value chains.

Digitalising a horizontal value chain involves integrating and optimising the flow of information from the customer to the supplier and back again, with the company in the middle. Therefore, business areas such as purchasing, production, logistics and planning are proactively connected together, as well as to those external value-adding partners who help meet your customers’ needs.

Digitalising a vertical value chain, on the other hand, is designed to ensure a continuous flow of information and data from sales to product development to production and logistics. If your production systems are intelligently networked together, you can increase both quality and flexibility, while also reducing costs.

Where are we today?

Market leaders have already digitalised and networked the functions along their vertical value chains. These include a digital ordering process, customer-specific product development, automated product data transfer to networked planning and manufacturing departments, and integrated customer service. Furthermore, these companies have also horizontally integrated inventory and planning data with suppliers, customers, and other value-adding partners.

This extensive yet necessary digitalisation in a company’s horizontal and vertical value chains disrupts the old ways of working and leads to massive changes in all areas of the company. If your goal is to completely overhaul your existing processes and business models through digitalisation, we speak of digital transformation.

The Digital Transformation Index

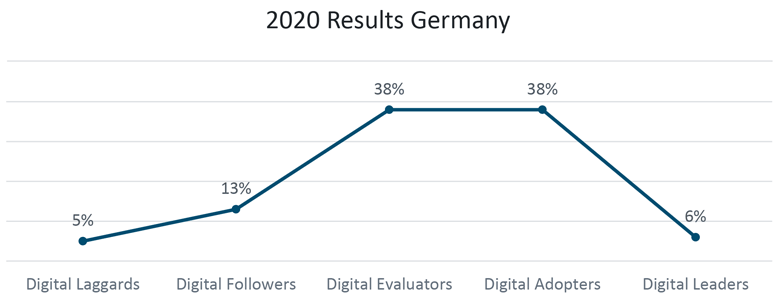

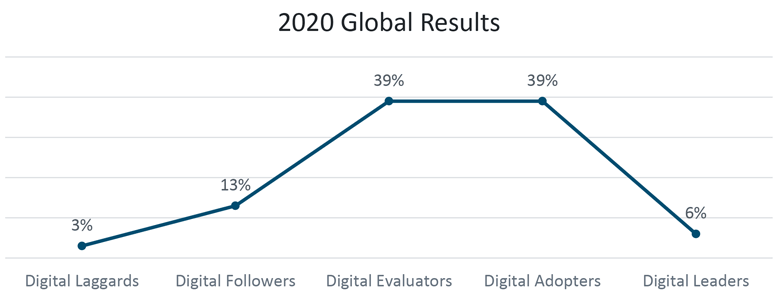

Based on research by DELL Technologies, which publishes a Digital Transformation Index every two years, it would appear that companies in Germany have understood the importance of digitally transforming their current processes, but that very few have made space for this in their corporate culture.

In order to get a better picture of how digital transformation is progressing worldwide, DELL places the companies it surveys into one of five categories:

- Digital laggards describe companies with the least mature digital transformation strategy. They don’t have a digitalisation plan and don’t really know how to invest in digital transformation.

- Digital followers are the second weakest group, making poor progress in digital transformation. They invest in a couple of isolated digital projects and are generally hesitant about future investments.

- Digital evaluators are in the middle. They are working slowly but steadily on digitally transforming their company, but are not quite there yet.

- Digital adopters are the second strongest group. As the name suggests, they already have an extensive digital transformation plan, which is being adopted at all levels of their business.

- Digital Leaders describe companies which have embraced digital transformation at all levels. Digitalisation is part of the company’s DNA.

The graphs below show the percentage of surveyed companies in each category for 2020, both in Germany and worldwide.

What are the current obstacles to achieving digital transformation?

The COVID-19 pandemic has accelerated digital transformation in companies worldwide. However, 94% of companies continue to identify obstacles and challenges. According to the Digital Transformation Index 2020, the three biggest problems identified by European and specifically German companies are as follows:

- Lack of budget and resources

(Europe: 29 %, Germany: 28 %) - Difficulties extracting insights from the sheer mass of data

(Europe: 28 %, Germany: 34 %) - Concerns about data protection and cyber security

(Europe: 27 %, Germany: 31 %)

It is precisely these concerns which companies need to overcome to get the best out of their corporate data in our digital age.

Turn data into gold

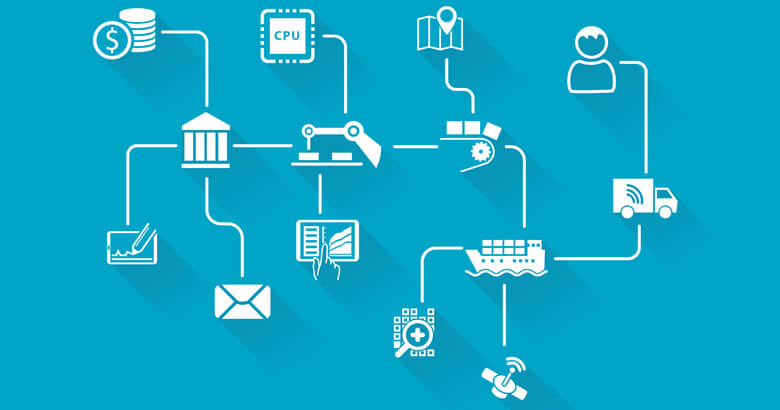

Data helps you optimise the way your company works and to identify new market opportunities and meet individual customer needs. Every day, companies collect a wide variety of data, from business information, logs, sensor data, transactional data and social media data. In order to gain useful insights from this sheer volume of data, it must be properly managed, collated, and analysed. However, collating your in-house and external data, getting it flowing, and performing analytics on it are all key to targeted marketing. And this enables you to tailor your approach to your customers and to tap into new sectors. There is an exciting wealth of technologies behind generating, collating and analysing data, including artificial intelligence (AI), the internet of things (IoT), cloud computing and machine learning . And these help data become an important asset for your company. Indeed, it’s the new gold.

How your company can benefit from exploiting its data

If you can sift the gold from your company’s data, you could benefit from the following advantages and opportunities:

- Increase your revenues

- Make workflows more efficient

- Reduce your overheads

- Experience a greater level of innovation

- Discover how you can optimise your production processes

- Improve in-house collaboration

- Better integrate customers and suppliers

- Facilitate better remote troubleshooting and maintenance for your equipment

- Learn to better identify and solve problems

- Minimise repeated errors and bugs

- Bring experts together and employ them at the right stage in the value chain

- Facilitate targeted, cross-departmental collaboration

- Minimise the silo mentality in your company

- Enable flexible, remote working from anywhere

- Induct new employees faster

- More targeted training courses and further development

- Understand your customers and staff better

- Increase customer satisfaction and retention

- Improve customer relationship management

- Increase staff satisfaction and retention

Benefit from the above by actually using the data which is coursing around your systems. This is a first yet essential step towards digitally transforming your value chains.

SEEBURGER can offer you solutions to implement end-to-end data logistics along your value chains. These enable you to create innovative business models for your markets based on digitalised processes. And you, too, can reap the benefits of digitalisation.

[1] Cf. Nutzen sie Digitalisierungspotentiale über ihre Wertschöpfungskette…! – Business2Service [Use the digitalisation potential in your value chain] (accessed 7th Oct 2021).

[2] cf. Digital Transformation Index | Dell Technologies US (accessed 8th Oct 2021).

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Rolf Wessel

Rolf Wessel has been product manager at SEEBURGER for software applications and services for electronic business data exchange since 2010. His focus is on solutions for SAP, electronic invoicing (e-invoicing) and innovations for the digitalization of business and technical business processes. The Forum elektronische Rechnung Deutschland (FeRD) appointed Rolf Wessel as an expert. As project manager at the United Nations Centre for Trade Facilitation and Electronic Business (UN/CEFACT), he develops international trade facilitation and establishes standards for electronic business processes. Furthermore, he represents the German delegation of the FeRD at the Franco-German workshop with the Forum National de la Facture Electronique (FNFE) and thus supports the government initiative for international standardization and harmonization of e-invoicing processes. He is a member of the working committee "Electronic Business" at the German Institute for Standardization. (DIN) and Association for Electronic Invoicing (VeR). Rolf Wessel graduated in business informatics (FH) with a focus on financial management and production planning. After working in the electrical, financial, consumer goods, software and mineral oil industries, he had been a systems analyst and IT project manager in the retail and logistics sector from 2003 to 2010.