Formel D – Logistics services for the Automotive Industry

Formel D’s business model encompasses services along the entire automotive value chain. As a global service provider for automotive manufacturers and suppliers, Formel D carries out a wide range of processes on behalf of customers – from product development and production to aftersales. And our core values for all of these are speed, reliability, transparency and flexibility. Therefore, we rely on seamless digital processes, and, with SEEBURGER’s support, deep integration into our customers‘ IT systems.

Formel D operates a superbly equipped 1,500 m² technical centre, 115,000 m² of parking space for around 6,000 vehicles and – coming soon – a specialist centre for electro mobility. This enables the company to supply players in automotive production with high-quality parts, to carry out full quality assurance processes and to coordinate transportation between OEM and dealerships.

We carry out projects for our customers, who are well-known OEMs or suppliers. Anyone involved in supply chain management will know that this type of work leaves no room for manoeuvre. Projects are complex, must keep to schedule, and are at the heart of the auto industry. While projects for suppliers mainly involves time-critical, sequential logistics of materials for product development or production, contracts from OEMs tend to require moving and tracking whole fleets of vehicles.

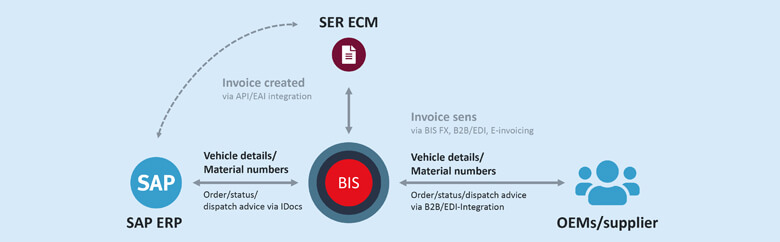

We use the SEEBURGER Business Integration Suite to receive these orders. The orders arrive as standardized B2B/EDI messages and the BIS automatically enters them into SAP based on vehicle or material numbers. As each further step is completed, BIS documents this in SAP, sends the customer a status update, and verifies details with the customer’s ERP system.

“In order for us as a service partner to keep the pace expected by the automotive industry, we need the right IT infrastructure. This not only needs to trigger processes in our system by a click of a customer’s mouse, it also needs to document every step taken – in real time.”

Transparent distribution logistics for OEMs

Formel D handles the shipping of brand-new cars to global markets for a German premium manufacturer. When these arrive at the distribution hub in Ahlhorn in Northern Germany, everything has already been prepared. A binding delivery date has already been set. The cars are parked according to the customer’s instructions and prepared before being sent on; some may receive a further coating, others may need winter tyres or other additions. The large technology centre on site is brilliantly equipped for this work. Then, the vehicles are sent on by road, rail or ship. Formel D sends any cars which don’t need additional quality work straight on to their destination. The respective vehicle data, dimensions and destinations are transmitted by the OEM and broken down by type by BIS 6.

If a vehicle is being exported abroad, then a smooth flow of data is important for so many reasons. In addition to the standard processes handled by EDI, there are also customs documents to be assigned. The manufacturer sends Formel D these documents as pdf files. Each form must be correctly collated, printed out and assigned to the right car. The car then needs to be found – is it in the parking lot or currently in the technical centre? Various departments then need to be notified and the OEM informed that the paperwork has been filed.

The manufacturer receives automatic notifications for everything done to a vehicle the entire time it is in Formel D’s care, and so always knows what is happening. Once a loaded car transporter sets off, the manufacturer can then inform the consignee, initiate subsequent processes and schedule the next steps. BIS 6 therefore not only handles the entire logistics process, but also securely and reliably communicates all the steps along the way so that those involved have the information they need to plan effectively and ensure that distribution is successful.

Speedy materials logistics for vehicle manufacturers and suppliers

Contracts concerning vehicle development, production or quality assurance generally come from suppliers who already use our logistics and warehousing services. In all the testing and validation processes, assembly work or customisation we carry out for our customers, we depend on good parts management. This includes the complex logistics involved in getting the right parts to a customer’s plant at the tight time and in the right sequence.

We use BIS 6 to handle the communication between Formel D and our customers. As the ERP systems either side synchronise in real time, the customer is able to compile pick lists and trigger items to be removed from the warehouse with a mouse click, just like it were his own system. Every action is immediately confirmed by the system. Delivery notifications are triggered and the customer knows exactly when he can expect delivery.

Some suppliers may still be running older systems which contain elements such as free text fields. The information placed in these needs to be processed individually by Formel D’s system. BIS 6 identifies this data and places it directly in a dedicated field in Formel D’s SAP system- without needing a hot folder! BIS immediately enters the transmitted data into the database and tells the customer’s outbound system once this has been completed; another example of its inbuilt end-to-end monitoring function.

How well such old EDI systems can work – and synchronise – with more contemporary systems can be seen in the impressive example of an 30 year old system developed by SEEBURGER itself – WinElke. An early iteration and long-time predecessor of today’s BIS6, amazingly it is still sometimes found in use at successful small businesses, whose one remaining component for the automotive industry is still in demand. On Formel D’s side, BIS6 patiently queues, throttles and tweaks notifications so that the much older system on the other side can happily receive them.

Digital invoice workflow with individually defined accompanying documents

The billing for these complex projects has been personalised and automated for Formel D through the API integration of an Enterprise Content Management System and individualised invoicing over SEEBURGER’s Business Integration Suite.

Better logistics through automated data flow

For the demanding business conducted by Formel D, speed, reliability and flexibility are of utmost importance. The successful multi-player therefore uses digital processes wherever possible. These require Formel D’s own IT systems to be deeply integrated into customers’ own systems. And that’s what SEEBURGER BIS 6 makes possible. BIS 6 handles the crucial EDI communication with our customers by synchronising the ERP systems with one another.

The biggest challenges in these tightly networked processes are to standardise and automate the flow of data. “As a rule, we are always dealing with at least two different ERP systems – our customer’s and our own. And these have different EDI structures. That means that data doesn’t simply flow from A to Ba. It needs to be converted first. And that’s what SEEBURGER deals with for us.“

BIS 6 provides a stable foundation for Formel D’s successful business. Integration networks all the systems we need and lets processes be completed digitally, as well as standardised, accelerated and optimised. And looking forward, the infrastructure can be easily used for Formel D’s growing portfolio; with BIS as the hub, processes, volume and connections can be scaled up to whatever we need.

Digitalisation with SEEBURGER as your business partner

Our decision to use the BIS platform, which has always managed whatever demands we have placed upon it, was not just for the technology. SEEBURGER has proven themselves to be a strong, reliable partner, which knows the automotive industry like no other integration company. Formel D and SEEBURGER benefit from a multitude of common customers, and comprehensive knowledge of logistics processes – on both sides. And with SEEBURGER’s help, Formel D can comfortably implement and develop their full range of services.

Learn more about digitalization in the automotive industry

“For us, BIS 6 is the first choice when it comes to distributing data. Being able to transmit data with flexibility, security and speed is becoming increasingly important in the automotive industry. And this is true in every process, from development to delivery to billing.”

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Stefan Pieper

Stefan Pieper has been at the Formel D Group since 2012. As an ISMS and IT project manager, he is responsible for Formel D’s global integration platform, as well as heading up and carrying out various projects. These projects concern matters such as EDI, e-invoicing, MFT, API/EAI and ECM.