Communication Standards in IoT and IIoT

For seamless communication between applications, devices and machines and with corporate IT systems, a uniform communication basis is necessary – one aspect is communication standards. The two most important standards in this context are OPC UA and MQTT. How do these IoT standards work and how are they used? This part of our IIoT and Industry 4.0 series provides an overview of these two most common standards for information exchange.

Would you like to start by learning about the basics? Then read our introductory blog on ‘What is IIoT and Industry 4.0‘. In another article we have compiled practical examples that illustrate how production and business processes can be optimized by IIoT and Industry 4.0. Furthermore we talk about the challenges companies have to deal with when implementing IIoT solutions. In this article we take a closer look at the most important communication standards for IIoT and Industry 4.0.

Standards for Secure Communication in IoT und IIoT (Industry 4.0)

In the (industrial) Internet of Things, physical systems such as industrial plants, machines, sensors, mobile devices and applications are connected to the virtual world.

- The digitization of production enables the data generated by the machines to be used along the entire value chain.

- In smart homes, sensors measure status information such as room temperature, brightness or humidity and send this information to mobile devices, from where control commands can be sent back.

- On the road to autonomous driving, connected cars interact with each other, with back-end infrastructures or via the cloud.

The prerequisite for all components networked in these exemplary digital ecosystems to be able to communicate with each other is a semantic description of machines, sensors, devices and production plants. In this context, existing systems represent a particular challenge. They are usually very heterogeneous, often individually designed for a specific application, often using components from several different manufacturers. For this purpose, communication protocols must be defined and used that are industry-neutral and hardware-independent. This is the only way to ensure communication between hardware, software and machines from the store floor to the top floor (ERP software), from microchip to smartphone. This requires a uniform ‘language’ that acts as a translator between all these systems – the so-called standards.

MQTT and OPC UA – Standards for Very Different Applications

MQTT (Message Queuing Telemetry Transport) and OPC UA (Unified Architecture) have emerged as the most successful standards for communication in IoT/IIoT.

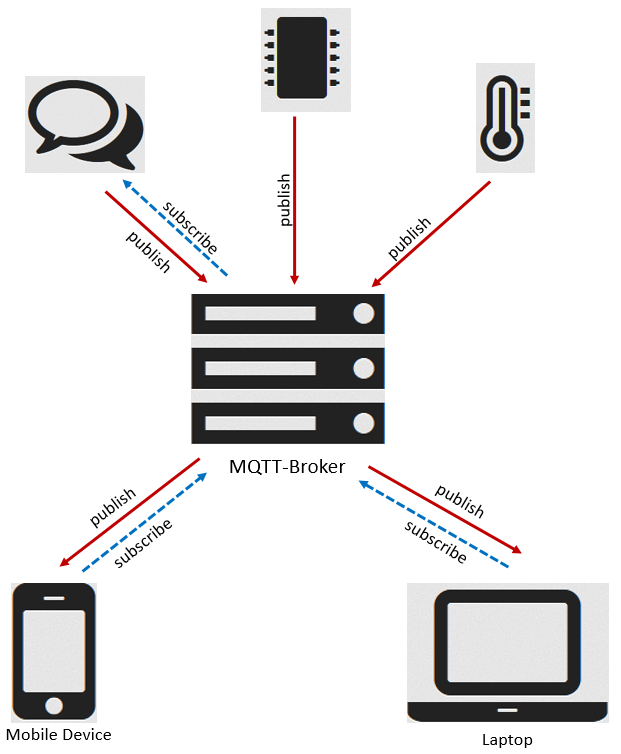

MQTT – an Efficient M2M Communication in (I)IoT

MQTT is an event-driven publish/subscribe architecture. The connection between the devices is not direct (end-to-end), but via a central server (broker), to which the sender and receiver of data each connect. Since the broker permanently maintains the status of all connected devices, this very lightweight and easy-to-implement protocol is particularly suitable for connections over long distances and unreliable networks. Originally developed in 1999 for satellite communication, MQTT is now very well suited for use with microprocessors for example for transmitting temperature data in smart home systems or for sending and receiving messages from messaging services. Each of the messages sent by the client contains the complete user data as well as a so-called ‘topic’.

The syntax of these is similar to a folder structure (e.g.: ground floor/conservatory/humidity sensor/humidity) and can be subscribed to by the client at the broker depending on the ‘topic’. The user will be informed by the broker when new messages for this topic arrive. Different quality of service levels can be defined.

MQTT Quality-of-Service-Level (QoS):

The QoS ensures that the message it sends reaches the recipient. For this purpose, three different QoS have been defined with which a message can be sent:

- At most once (0): a message is delivered a maximum of once, regardless of whether the recipient confirms receipt or not.

- At least once (1): a message is delivered at least once. If no acknowledgement of receipt is sent, the sender must resend the message.

- Exactly one (2): a message is delivered exactly once. To guarantee this, MQTT uses a two-stage acknowledgement of receipt.

Further features that define the way in which messages for a certain topic can be deposited with the broker by the client and retrieved from there by the subscriber are so-called retained messages, last will and testament or persistent sessions.

As a very easy-to-use and resource-saving protocol, MQTT has become the standard protocol, especially for IoT communication, and is the basis of many IoT applications such as Condition Monitoring.

OPC UA – For Secure Platform-Independent Data Exchange

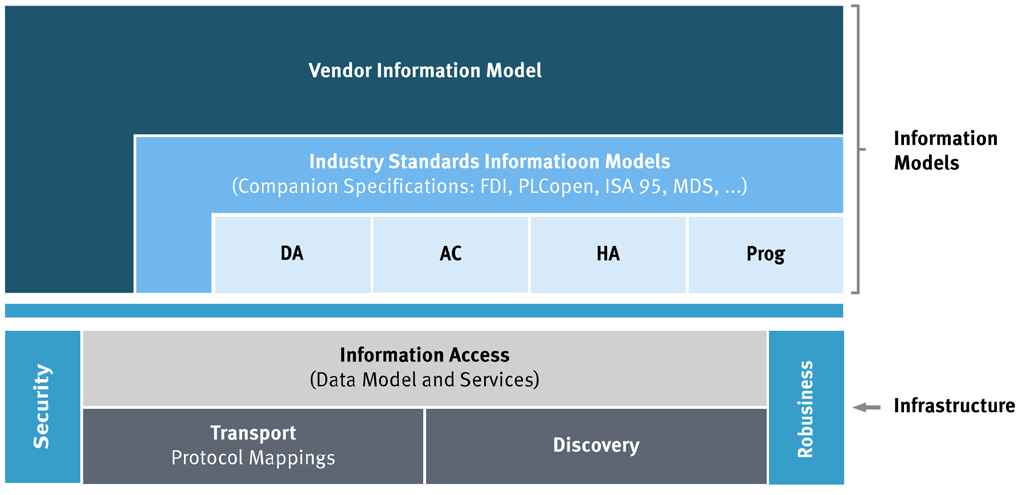

The acronym OPC UA stands for Open Platform Communications United Architecture. This enables standardized and secure industrial communication from machine-to-machine or PC-to-machine and other systems. The ultimate goal of OPC UA is platform independence and interoperability, a core requirement of Industry 4.0.

OPC UA is to be seen as a framework that publishes its own information models in the so-called Companion Specifications. Developed by expert committees these are standardized for industry-specific applications and objects for similar machines and systems.

By providing simple interfaces and describing the semantics within the messages, interoperability is ensured because the uniform format, the defined structure and the common vocabulary enable applications in the OPC UA environment to understand the messages. The data is provided via an OPC server in the network. This is connected to the OPC client from which the data is read.

In order to use OPC UA as a standard for IIoT applications for communication in the context of Industry 4.0, an Internet Protocol (IP) based network is required. This requires that access to data and services of the machines corresponds to all aspects of IT security. OPC UA has security features and IT mechanisms for authentication, signing and encryption already anchored in the standard. It is therefore not only suitable for connecting machine data streams within closed networks, but also for connecting individual machines or, for example, from production to new digital services via IoT platforms.

SEEBURGER accelerates the business of over 10,000 customers. Our central hybrid integration platform, the SEEBURGER Business Integration Suite (BIS), offers solutions for IoT/IIoT. It also includes adapters for OPC UA and MQTT to implement IoT/IoT 4.0 scenarios in enterprise architectures. It networks things, systems, applications, customers and partners. This ensures that the right data in the right format reaches the right place at the right time – within and between companies.

The Business Integration Suite is ‘made by SEEBURGER’ and ‘made in Germany’. It includes B2B, EDI, MFT, EAI, API and (I)IoT integration capabilities available in any cloud, hybrid or on-premises.

Webcast on demand

Learn more about Business Integration in IIoT: Scenarios and How Does it Work With BIS

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Dr. Marcus Schneider

Dr.-Ing. Marcus Schneider works in SEEBURGER Research on the shop floor to top floor integration of extensive data streams in the area of IoT and Industry 4.0, especially on the basis of modern standards such as OPC UA. He did his doctorate from the Karlsruhe Institute of Technology (KIT) on information management in the collaborative assembly of variant-rich products. As project manager in the BMBF-funded (Bundesministerium für Bildung und Forschung = Federal Ministry of Education and Research) project KoKoMo (Kompetenz Kollaborative Montage = Competence Collaborative Assembly) he was involved in the prototypical implementation of integration solutions in several use cases of industry partners based on the SEEBURGER Business Integration Suite.