Achieving “Last mile” delivery success is key to becoming a “Digital Ready Enterprise”

The 2017 Holiday Season has just ended. As a retailer, how do you think you performed around key KPI’s –especially last mile delivery? Did you miss some delivery times? Did you ship in multiple separate shipments from different locations? Were consumer “delivery” complaints higher than planned? If so, then perhaps some technical tweaking is required around your last mile delivery process and now is the time before 2018 Holidays are upon us.

The 2017 Holiday Season has just ended. As a retailer, how do you think you performed around key KPI’s –especially last mile delivery? Did you miss some delivery times? Did you ship in multiple separate shipments from different locations? Were consumer “delivery” complaints higher than planned? If so, then perhaps some technical tweaking is required around your last mile delivery process and now is the time before 2018 Holidays are upon us.

We are now fully aware that e-commerce coupled with smartphone and internet technologies is causing a massive increase in online ordering. According to Datatex, “It is expected that in 2018 online ordering will reach 1.35 billion which is a 28.8% increase from 2013.” The challenge -for some retailer and their partners- will be meeting the consumer guarantee delivery promise by dates. If not met, consumers will shop elsewhere.

To deliver the massive amount of online orders requires various systems: Warehouse Management, Distributed Order and Transportation Management systems. Each of these systems play a critical role in last mile delivery as they must coordinate a larger number of dynamic events taking place across the network. For instance, the following is a small sample of the events that they require sharing:

- Where is the inventory located both across Distribution Centers and where inside the Distribution Center

- How many items are in stock and where they are located to reduce multiple shipments

- What are the product attributes so they match the proper packing solution

- Provide cross network product visibility during its journey for all network delivery partners and consumers

Given the number of system touchpoints within the network, there is a very large amount to data being generated. It is essential that this data be shared and monitored for exceptions so that delivery milestones can be reached.

So it is reasonably fair to say if the data is correctly integrated across all system, then delivery times- barring other non-data related issues- can ‘more than likely’ be consistently met. The integration challenge, of course, is connecting to the variety of disparate platforms mentioned above (e.g. Transportation, Warehouse or Distributed Order Management system, etc.) whether they be on premise or in the cloud.

The type of middleware needed to meet these challenges would require, at minimum, the following:

- Integrate both on-premises and cloud platforms to align with business application portfolio strategy

- Have a flexible delivery model – either on premise, cloud or hybrid to align with IT and business needs

- Provide one stop shopping for all integration scenarios (e.g. EAI, B2B, API, or MFT) to reduce costs and complexity

- Be configuration based and less development based to quickly get projects to the market faster

- Process oriented to efficiently execute complex workflow steps that align with consumer delivery demands

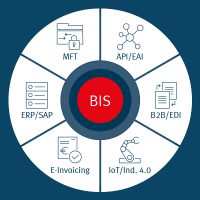

SEEBURGER provides just the middleware solution that meets these requirements; it is called Business Integration Suite (BIS). BIS is a hybrid and ‘one stop’ shopping integration platform.

Learn more about SEEBURGER Business Integration Suite

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Brent Tisdale

Brent Tisdale is a Vice President of OmniChannel Sales at SEEBURGER, a global market leader in business integration software. He has more than 30 years’ experience working for luminary companies like IBM and General Electric where he has streamlinedcomplex business processes for many industries including Retail, CPG and Discrete Manufacturing. He has a Six Sigma Greenbelt earned from his years with GE which he utilizes to gain a deep understanding of business process challenges and the suggested integration options. He was the Co-captain of the 1979 Holiday Bowl Champions. The first Bowl game ever won by Indiana University (Bloomington) Football team.